EARLY FAILURE

|

|

Causes:

- Abnormal axial load or excessive load caused by an expanding shaft

- Shaft bending or misalignment

- Poor parallelism of inner and outer rings

- Inadequate lubrication

|

Preventive Measures:

- Allow the outer ring to pass with clearance to ensure free axial movement of the moving end

- Proper alignment of the shaft and bearing housing

- Review the type and quantity of lubricant

|

STIFFNESS

|

|

Causes:

- Darkening of the ring

- Operating above the speed limit

- Poor or incorrect lubrication

|

Preventive Measures:

- Check clearance and bearing internal clearance

- Review the type of bearing

- Control the selection of suitable lubricant and lubrication quantity

|

DAMAGE

|

|

Causes:

- Excessive interference fit

- Large bearing clearance

- Excessive shock load

|

Preventive Measures:

- Check interference fit tolerances

- Rectify the pah radius

- Check the load conditions

|

NOTCHING

|

|

Causes:

- Impact during assembly

- Contamination

- Excessive static load on the stationary bearing

|

Preventive Measures:

- Clean the shaft and housing

- Improve the sealing element

- Check the load conditions

|

FRICTION

|

|

Causes:

- Application of vibration to a stationary bearing (sudden shock load)

- Very small clearance on the pass surface

|

Preventive Measures:

- Place the shaft and housing during shipment

- Apply pre-load. Use oil for lubrication

- Increase tightness

- Apply oil

|

SLIDING

|

|

Causes:

- Excessive axial load

- Incorrect alignment of the bearing

- Poor lubrication

- Foreign matter entering and causing loosening

|

Preventive Measures:

- Correct your assembly

- Review load conditions

- Choose the right lubricant

- Improve the sealing element

- Avoid sharp speeds

|

WEAR

|

|

Causes:

- Foreign matter and corrosion

- Inadequate and incorrect lubrication

|

Preventive Measures:

- Improve the sealing element

- Clean the shaft and housing

- Check the type and quantity of lubricant

|

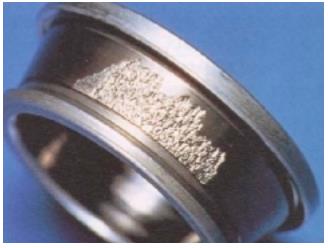

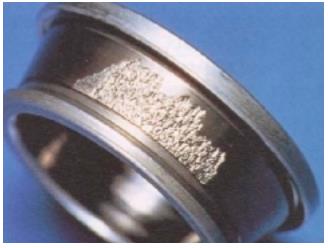

RUST - CORROSION

|

|

Causes:

- Incorrect storage and cleaning

- Abrasive gas, liquid, or water

- Chemical function of the lubricant

|

Preventive Measures:

- Check the cleaning oil

- Review the corrosion prevention method

- Improve the sealing element

- Avoid direct contact with bare hands

|

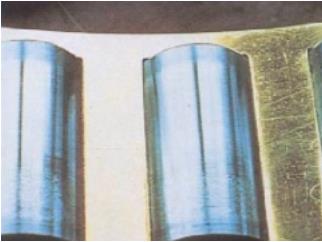

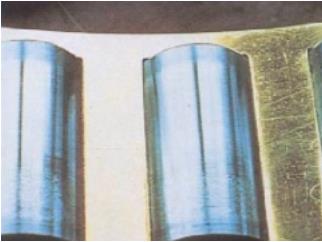

CREEPING

|

|

Causes:

- Insufficient tightness

- Insufficient tightened sleeve

- Insufficient surface pressure

|

Preventive Measures:

- Check clearances

- Tighten the sleeve

|