Roughness may occur on the surfaces obtained through machining or chipless machining due to the production. While some these roughnesses can be visually observable and sensible with hands, depending on the applied manufacturing type they can also be of a size that can be detected and measured with some precision control devices.

In order to reduce wear on machine parts and to make the surface look better, these roughnesses have to be at certain values. Therefore, the roughness values surfaces will be treated with, its method, and some other properties must be illustrated on a figure.

Even the most precisely treated surfaces contain roughness. If there was no surface roughness present, it would be impossible to separate two superimposed surfaces because there would be no air between two surfaces with zero roughness values. Even though roughness value can never be zero, it can be minimized. Smoother surface treatments increase quality but are expensive.

|

Surface Treatment Marks |

Explanation |

|---|---|

|

|

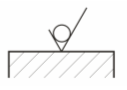

Used when no machining is required or the surface should remain as it is. |

|

|

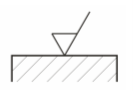

Used as the mark for surfaces obtained through machining. |

|

|

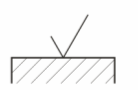

Used as the mark for surfaces obtained through any manufacturing method. |

|

|

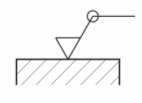

It is used by adding a circle to the symbol when all surfaces of a part are of the same surface quality. |

|

|

When it is desired to indicate special surface conditions, this mark is used by adding a horizontal line to the symbol's long line and then by writing the method of processing or a special case on the horizontal line. |

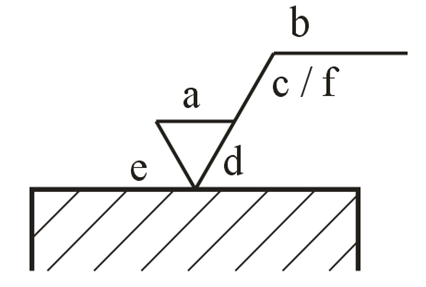

Symbols Added to Surface Treatment Marks

|

|

a: Roughness value in m (micron) with Ra symbol |